Desalination Unit Industrial Reverse Osmosis System Uf 100T/H+RO

70T Effluent Treatment Plant

Desalination Unit Reverse Osmosis System & Ultrafiltration 100T / H

+ RO 70T PVDF Oily Wastewater Reuse Treatment Plant 8040

| Items | Commodity | Brand | Quantity |

| 1 | Original pool | User built | 1 set |

| 2 | Original water pump (CDLF120-20-2) | Southern Hangzhou | 1 set |

| 3 | Bag filter CK-650-810-5 | Our company | 1 set |

| 4 | Ultrafiltration (UF) device Water production: 100m3/h, bacteria,

microbe removal rate: ≥99%, system water utilization rate: ≥85% | 1 set |

| 6 | Backwashing dosing system SEKO-800 | Italy | 1 set |

| 7 | Cleaning water tank (3.0m3) | Guangdong | 1 set |

| 8 | Cleaning filter CK-550-810-4 | Our company | 1 set |

| 9 | Ultrafiltration tank | User built | 1 seat |

| 10 | Connecting pipe fittings: using food grade UPVC pipe valve parts | Nan Yi | 1 batch |

| 11 | Electronic control system | Our company | 1 set |

| Total control cabinet: Taiwan Weilun man-machine interface touch

screen, Japan Mitsubishi PLC programmable controller automatic

control, Danfoss / Delta variable frequency soft starter, France

Schneider contactor, thermal relay, knob switch, indicator light,

Korean pressure control , time controller. | |

| 12 | Pressure gauge | China | 1 batch |

| 13 | Pipe flowmeter | China | |

| 14 | Handheld TDS pen | China | 1 pc |

| 15 | Handheld PH pen | China | 1 pc |

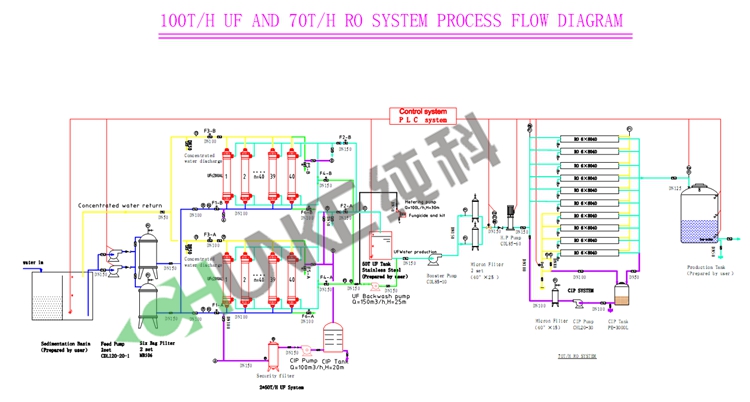

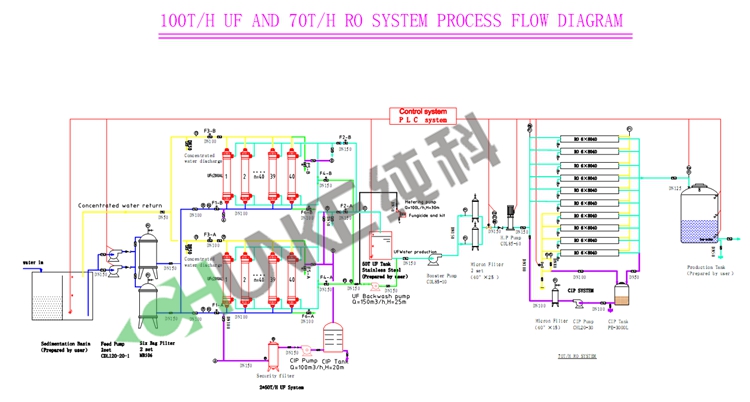

Water Treatment Process flow diagram

Use for:

(1) Pretreatment of reverse osmosis feed water, high efficiency,

compact ultrafiltration due to high filtration precision, can

provide maximum protection for reverse osmosis membrane

(2) Advanced treatment of large and medium-sized drinking water

plants

(3) Municipal and industrial wastewater treatment: Ultrafiltration

can provide better treatment results than traditional treatment

processes, and realize the reuse of water and wastewater.

(4) Recycling treatment of circulating sewage

(5) Recovery of useful substances in sewage

(6) Preparation of mineral water, de-bacterification of drinking

water and well water, removal of various suspended solids and

colloidal impurities in water, especially removal of pathogenic

microorganisms such as cryptospores, flagellates and Escherichia

coli

(7) Sterilization, clarification, purification and separation of

oral liquid and biological products

(8) High purity water terminal treatment

(9) Concentration and separation of juice, protein and enzyme

preparations

Pure water and ultrapure water equipment; medical sterile

pyrogen-free water equipment, industrial beverages, drinking water,

mineral water purification, industrial separation, concentration,

purification, industrial wastewater treatment, electrophoretic

paint, electroplating oily wastewater treatment. The

ultrafiltration membrane equipment produced has many varieties and

specifications. In the design, it has absorbed advanced technology

from the same industry in foreign countries. The filtration working

pressure is below 0.3Mpa, and the ultrafiltration membrane

specifications are 4 inches, 6 inches, 8 inches, 10 inches and so

on.

The ultrafiltration membrane equipment has reasonable design,

beautiful appearance, strong versatility, exquisite materials, and

durability. Stable chemical properties, strong corrosion

resistance, acid, alkali, salt corrosion (pH: 0 ~ 14), non-toxic,

odorless, light weight, high strength (high temperature, high

pressure), labor-saving operation. Various types of tubular

ultrafiltration membrane equipment are widely used in petroleum,

chemical, juice, light industry, pharmaceutical, food, resource

development, metallurgical coal, national defense industry,

environmental protection and other fields.